Vacuum Circuit Breaker: Superior Protection for Critical Equipment

In modern electrical systems, protecting critical equipment from faults, overloads, and operational disruptions is a top priority. A Vacuum circuit breaker (VCB) provides superior protection, ensuring safe and reliable operation for industrial plants, commercial facilities, and utility networks. With fast fault interruption and minimal maintenance requirements, the vacuum circuit breaker has become the preferred solution for safeguarding high-value equipment.

What is a Vacuum Circuit Breaker?

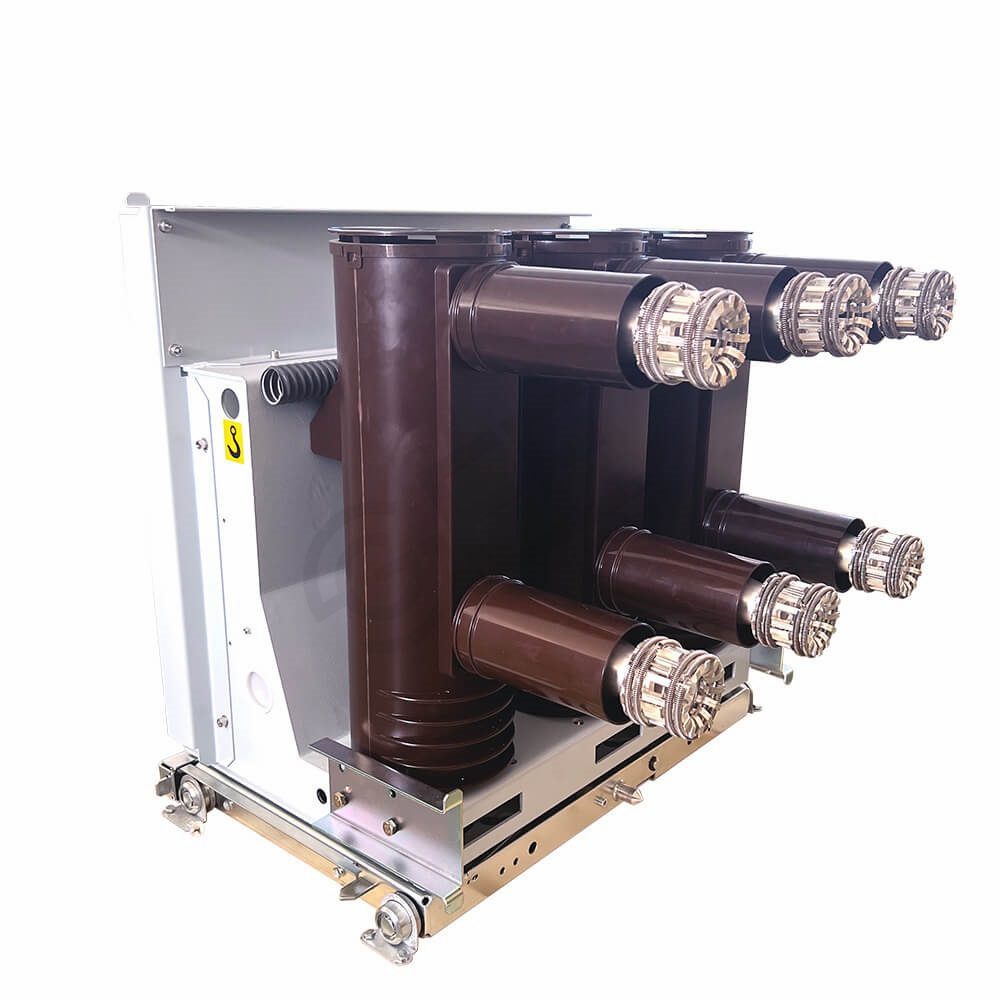

A vacuum circuit breaker interrupts current by extinguishing electrical arcs within a sealed vacuum. Unlike air or oil circuit breakers, the vacuum circuit breaker uses a vacuum interrupter to quench arcs almost instantaneously, reducing contact wear and enhancing operational reliability. Its compact design and durability make it an ideal choice for applications where critical equipment protection is essential.

Key Benefits for Critical Equipment Protection

1. Fast and Reliable Fault Interruption

A vacuum circuit breaker reacts almost instantaneously during electrical faults, such as short circuits or overloads. This fast response prevents damage to sensitive and expensive equipment, ensuring minimal downtime and uninterrupted operation. Facilities rely on vacuum circuit breakers to maintain the integrity of their critical systems.

2. Minimized Equipment Wear

By rapidly extinguishing arcs within a vacuum, the vacuum circuit breaker minimizes electrical and mechanical stress on connected equipment. This protective feature prolongs the life of transformers, motors, generators, and other critical assets while maintaining optimal operational efficiency.

3. Long Lifespan and Low Maintenance

The sealed vacuum interrupter prevents oxidation, dust accumulation, and contamination, reducing maintenance requirements. A vacuum circuit breaker provides long-term reliability, allowing facilities to focus on operations instead of frequent servicing. This low-maintenance design reduces overall operating costs.

4. Compact and Flexible Design

Modern switchgear often faces space constraints. The vacuum circuit breaker’s compact and lightweight design allows easy integration into existing panels and switchgear layouts. This flexibility ensures that critical equipment remains protected without requiring large, bulky installations.

5. Environmental Safety

Unlike oil or SF6 circuit breakers, a vacuum circuit breaker contains no hazardous liquids or gases, making it environmentally friendly. Facilities using vacuum circuit breakers enhance safety for personnel while meeting environmental regulations.

6. Versatile Applications

Vacuum circuit breakers are suitable for a variety of environments, including industrial plants, commercial buildings, renewable energy installations, and utility grids. Their consistent performance under different operational conditions makes them a trusted solution for protecting critical equipment worldwide.

7. Compliance with International Standards

High-quality vacuum circuit breakers comply with international safety and performance standards, ensuring reliable protection across global markets. Facilities can deploy vacuum circuit breakers with confidence, knowing they meet rigorous operational and safety requirements.

Conclusion

For facilities that rely on critical equipment, a vacuum circuit breaker offers superior protection, fast fault interruption, low maintenance, and environmental safety. Its durable design and compact footprint make it ideal for industrial, commercial, and utility applications.

By installing a vacuum circuit breaker, organizations can safeguard high-value assets, minimize downtime, and maintain operational continuity. For reliable, efficient, and long-lasting electrical protection, the vacuum circuit breaker is the solution facilities can trust.